At a high level, preventive maintenance runs on a set schedule, while predictive maintenance is driven by equipment health. Commercial buildings feel that gap most when breakdowns happen between planned visits and work turns reactive.

This article breaks down preventive vs. predictive maintenance, where each fits in for facilities, and how to build a hybrid plan that reduces downtime and budget surprises.

Predictive vs. Preventive Maintenance Comparison

The real difference between predictive and preventive maintenance is how maintenance decisions are made.

- Preventive maintenance is triggered by time or usage

- Predictive maintenance is triggered by what the equipment is actually telling you

Each affects labor planning, downtime risk, and how often failures catch your team off guard.

| Area | Preventive Maintenance | Predictive Maintenance |

| What triggers work | Calendar dates or runtime hours | Condition data and performance trends |

| Tools used | CMMS, checklists, service intervals | Sensors, controls data, analytics |

| Cost profile | Lower upfront, higher risk of doing work too early | Higher upfront, less wasted labor and parts |

| Downtime risk | Fewer failures than reactive work, but blind spots remain | Earlier warnings and better timing |

| Best fit assets | Predictable, low-risk equipment | High-impact, mission-critical systems |

Preventive maintenance brings structure and consistency to day-to-day operations, while predictive maintenance improves timing and focus by flagging issues earlier.

For most facility managers and business owners, the best results come from using both intentionally.

Preventive Maintenance Creates a Schedule that Stabilizes Operations

Preventive maintenance works because it creates discipline. Work is planned, repeatable, and documented, reducing guesswork and keeping teams from constantly reacting.

For most equipment and your vital systems (plumbing, HVAC, electrical, machinery, etc.), that consistency alone prevents a large share of failures.

In commercial facilities, preventive maintenance commonly covers:

- HVAC filter changes and routine tune-ups

- Chiller and boiler inspections

- Pump lubrication and belt checks

- Lighting, electrical, and life-safety inspections

- Standard plumbing checks

Where Preventive Maintenance Delivers the Most Value

Preventive maintenance works best in facilities when equipment failure isn’t likely to escalate quickly or cause a major disruption to your business.

It supports compliance requirements, keeps inspections predictable, and simplifies coordination across multiple buildings.

For portfolio operators, it also creates a shared standard that’s easier to manage at scale.

When executed well, preventive maintenance can reduce operating expenses by up to 18% and deliver a ~400% ROI by reducing breakdowns, improving energy efficiency, and extending equipment life.

Just as important, it smooths spending patterns.

Fewer surprises mean fewer uncomfortable budget conversations.

Predictive Maintenance is Condition-Based Work Triggered by Real Data

Predictive maintenance changes how teams decide when to intervene.

Instead of assuming risk based on time, decisions are made based on performance signals that show something is starting to drift out of range.

In building environments, predictive maintenance often includes:

- Continuous or periodic monitoring of critical assets

- Trend analysis to spot abnormal behavior early

- Alerts that trigger focused, timely work

The data that informs your maintenance decisions might include unusual vibration, rising temperatures, changes in the amount of power a motor uses, or patterns from building control systems.

These signals highlight problems that aren’t necessarily visible during your routine walk-throughs or inspections, giving you an earlier warning before something fails.

So, the intent isn’t constant intervention, but better timing.

Where Predictive Maintenance Delivers the Most Value

In many cases, predictive maintenance delivers the most value in buildings where failure causes outsized disruption (think a major HVAC breakdown during peak season or equipment that’s costly to access).

Facilities that use predictive maintenance often spend about 12% less, keep equipment running about 9% longer, and get roughly 20% more life out of their systems.

That means fewer last-minute breakdowns and more control over repairs, instead of reacting after something fails.

Signs Your Current Maintenance Approach Isn’t Working Anymore

- Emergency calls become a regular occurrence

- Overtime and after-hours work pileup

- Equipment fails between scheduled maintenance

- Systems run fine one month and struggle the next

- Equipment wears out earlier than expected

- There’s no clarity on what equipment and systems are healthy and which are at risk.

This is what happens when facilities rely on running to failure, mixed with scattered preventive maintenance.

That approach might save you a few bucks and work in simple buildings.

It breaks down fast as systems get more complex, operate for longer hours, or support revenue-critical operations.

Across industries, reactive maintenance costs 25–30% more than preventive work.

Manufacturing often sees the most visible impact, with roughly 800 hours of unplanned downtime per year and nearly $50B annually in losses. Auto manufacturing lines lose upwards of $22,000 per minute when stopped.

While the numbers look different elsewhere, the impact is similar. Hotels, restaurants, grocery stores, retail locations, and auto dealerships often run on thin margins (under 5%).

When systems fail unexpectedly, there’s little room to absorb the hit.

In those cases, preventive vs predictive maintenance becomes a way to protect margin and avoid disruptions the business can’t afford.

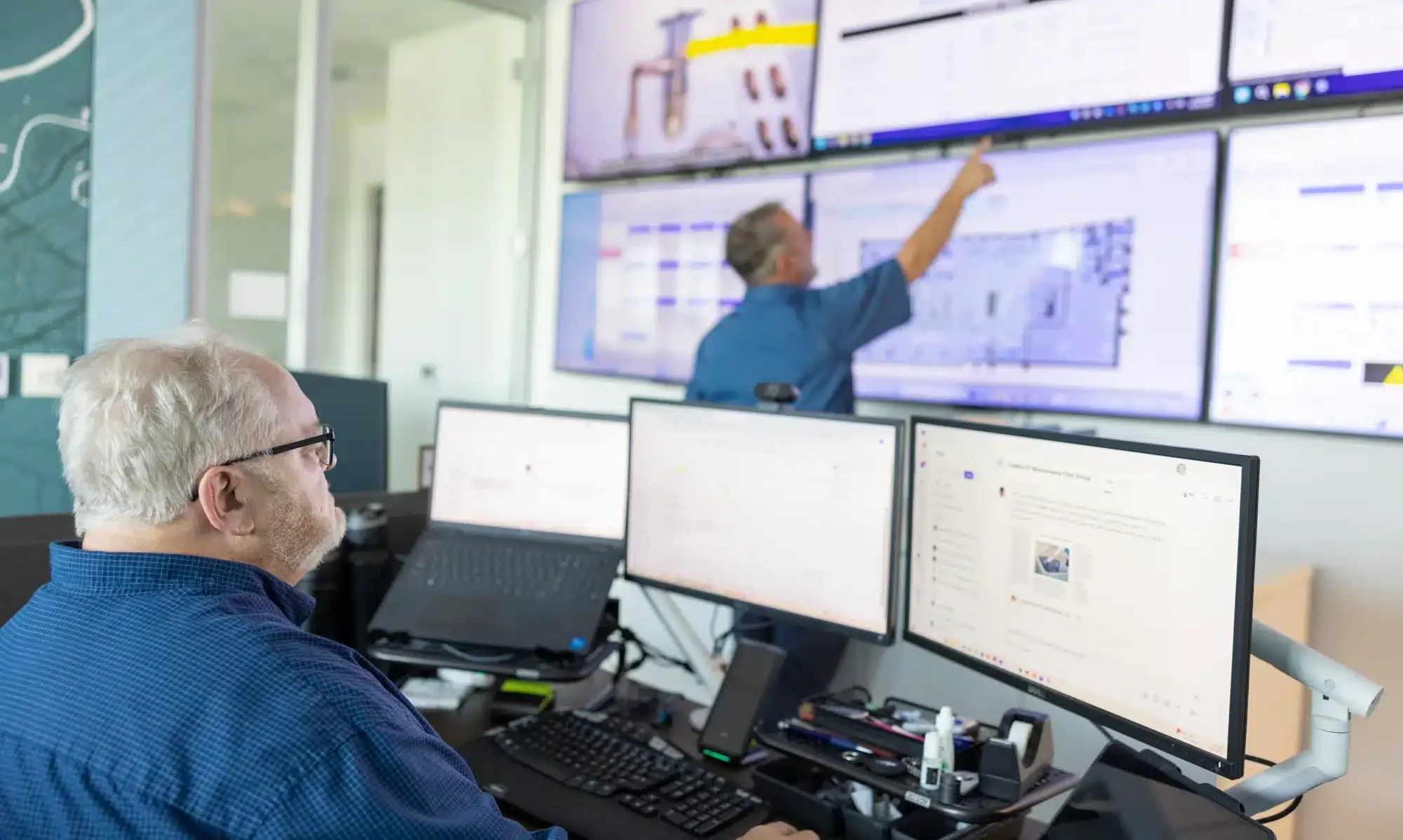

What Our Data Reveals About Planned vs. Reactive Maintenance at Scale

Facility leaders often ask whether shifting away from reactive work is realistic. Our internal data shows that it is, but only when maintenance programs are structured intentionally.

What We See Across Thousands of Facilities

Based on internal CRM and service data, we currently support:

- Approximately 15,000 individual facilities across the Southeast, which is around 4,500 commercial customers

- Roughly 2,000 active Facility Services agreements

- Around 30 Facility Management agreements

That range gives us visibility into both reactive-heavy environments and highly planned ones (often within the same industries).

There’s a Clear Contrast Between Planned vs. Unplanned Work

When we compare different service models:

- Facility Management (contract-based, ongoing management across systems) average ~80% planned work and ~20% unplanned

- Facility Services (work-order driven, reactive service calls) average ~35% planned work and ~65% unplanned

We find this gap doesn’t happen because of the industries, but structure, visibility, and follow-through.

What This Means for Facility Leaders

Facilities with higher percentages of planned work tend to see:

- Fewer emergency calls

- Better labor scheduling

- Less premium overtime and after-hours work

- More predictable maintenance spending

- Longer equipment life

Facilities stuck in reactive cycles usually aren’t ignoring maintenance; they’re just missing prioritization and early signals.

One of our senior facility service technicians puts it this way:

“Nine times out of ten, the equipment gives you a heads-up. The problem is nobody’s watching. Catch it early, and you can save a ton of headache and a ton of money.”

When Preventive Maintenance Is Good Enough

Some assets are predictable and low-risk. In those cases, scheduled preventive maintenance is often enough, especially when budgets or manpower are limited.

- Exhaust and ventilation fans

- Standard rooftop units

- Non-critical pumps

- Lighting systems

- Routine inspections required by code or policy

In these cases, simplicity is a strength. Scheduled work keeps systems reliable without adding cost or complexity that won’t pay off.

“Good enough” preventive maintenance means:

- Work gets done on schedule

- Findings are documented clearly

- Repairs are handed off cleanly when needed

For many businesses, consistency matters more than sophistication.

We help standardize calendar- and usage-based preventative maintenance, so your team stays on top of scheduling, documentation, and escalation without overbuilding the program.

Predictive Maintenance Changes the Game

Predictive maintenance makes sense when failure carries real consequences. If downtime creates safety risk, revenue loss, or serious disruption, guessing is expensive.

- Hospitals and healthcare facilities

- Data centers

- Manufacturing plants

- Large campuses with shared systems

- Buildings where HVAC failure during peak season would be detrimental

This is where failure economics kick in.

Repairs happen at night. Crews get pulled off other work. Tenants or customers get impacted. Leadership wants answers fast.

Predictive maintenance is a good choice for:

- Chillers and boilers during peak demand

- Critical production equipment

- Systems that repeatedly fail between PM visits

At this point, the question isn’t whether preventive or predictive maintenance is “better.” It’s where each one actually makes sense in your facility, based on risk, impact, and budget.

How to Build a Hybrid Maintenance Strategy

Preventive maintenance should be the foundation of your maintenance strategy. It covers the majority of your equipment and keeps day-to-day operations steady.

Predictive maintenance gets added in where failure would actually hurt (systems that are expensive to repair, hard to access, or disruptive when they go down).

A simple way to approach this is to tier your assets.

| Tier | If This Fails … | Recommendation | Equipment Examples |

| Tier 1 (Critical) | Operations stop, safety is at risk, or revenue is immediately impacted | Predictive + preventive maintenance | • Central chillers and boilers• Main electrical switchgear• Generators• Data room or server cooling systems• Critical production equipment• Primary air handlers serving large or sensitive areas |

| Tier 2 (Important) | Operations are disrupted, but the business can keep running short-term | Strong preventive maintenance with selective predictive monitoring | • Rooftop units• Secondary air handlers• Circulation and transfer pumps• Elevators• Compressed air systems |

| Tier 3 (Non-Critical) | It’s inconvenient, but manageable | Basic preventive maintenance or run-to-replace | • Exhaust and ventilation fans• Unit heaters• Small circulation pumps• Breakroom or non-essential equipment• Decorative or non-critical lighting |

This tiered setup makes capital planning easier as you gradually replace emergencies with controlled, predictable work.

Crews can be scheduled ahead of time. Parts can be ordered before they’re urgent. Emergency costs drop because problems don’t catch you off guard.

Implementation Roadmap for Facility Leaders

The cleanest way to roll out preventive and predictive maintenance together is to move in steps (not all at once).

Think of it like building a system, not flipping a switch.

- Take stock of where you are today

How much work is reactive? How much is planned? - Identify the assets that matter most

What causes the biggest disruption when it fails? - Start small with predictive maintenance

Pick 3-5 high-impact systems instead of everything. - Decide what counts as a real problem

Agree in advance what’s serious enough to act on, so alerts don’t get ignored. - Tie alerts into your work order process

If it doesn’t create a task, it won’t get fixed. - Train teams on how to respond

Everyone should know when to monitor, repair, or escalate. - Review results and expand by tier

Apply what works to the next group of assets.

If you’re not sure whether preventive or predictive maintenance makes sense for your facility, or you need help implementing a plan, we can help you sort that out.

We work with thousands of facilities across the Southeast to build practical maintenance plans that fit real operating constraints.

Contact us today to see where planned work can realistically increase.

FAQs About Preventive and Predictive Maintenance

What is preventive maintenance?

Preventive maintenance is scheduled work performed on building equipment, such as HVAC systems, electrical panels, pumps, and plumbing, to reduce the risk of breakdowns.

What are examples of predictive maintenance?

Examples include watching for unusual vibration in motors, rising temperatures in electrical equipment, higher power use in mechanical systems, or warning signs from HVAC and building control systems.

Is predictive maintenance expensive to implement?

Predictive maintenance can cost more upfront, but it often saves money by reducing emergency repairs and unplanned downtime.

Can I do predictive maintenance without new sensors?

Yes, many facilities use existing building controls, performance trends, and service history to catch problems early.

What’s the first step if my facility is mostly reactive today?

Start by identifying which equipment causes the biggest disruption when it fails, then focus maintenance efforts there first.