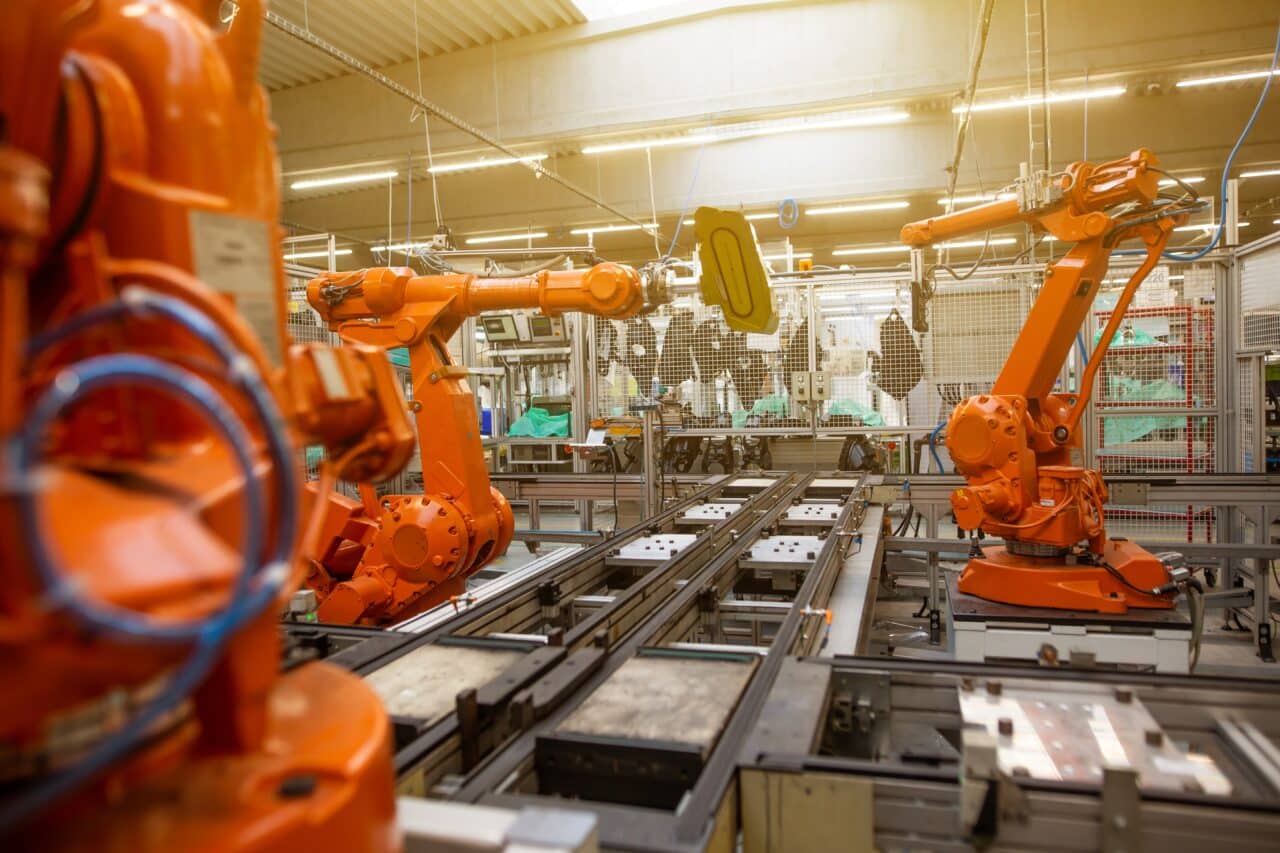

An automotive supplier responsible for stamping both steel and aluminum products had a challenge that needed a solution. The company’s compressor room was plagued with persistent issues, resulting in inefficiencies and increased operational costs. By adopting a straightforward yet effective approach, they not only identified the root causes of their problems but also found a reliable partner to address them.

Customer Goals:

- Create a solution to mitigate disruptions that hinder production and increased downtime in compressor room.

- Create a consistent flow of compressed air, as to not affect the quality and efficiency of their operations.

Solutions:

- Lee Company deconstructed the existing system and uncovered the opportunity to rebuild the compressor room for improved performance.

- They developed a plan to overhaul the compressor room, addressing both simple and complex issues. Rather than seeking a turnkey solution, they optimized the existing equipment, eliminating the need for costly replacements.

Results:

- Lee Company and the automotive supplier adopted a partnership approach — choosing a partner who shared the commitment to long-term success.

- By taking this approach, the automotive supplier not only optimized their compressor room but also enhanced their overall operational efficiency.

Smart People. Dedicated Partners. Creative Solutions.

For 80+ years, customers have trusted Lee Company to handle everything from HVAC to plumbing to electrical services; we are the established experts in installation, maintenance, and repair.

Today, with more than 1,600 professionals on the team, we’re the people facility managers call when they need collaborative partners, eager to tackle the toughest challenges.

We’re ready to create a solution just right for you.

Let's Talk!