Your commercial building’s HVAC system might not be the most exciting topic, but HVAC troubleshooting is essential for ensuring occupant comfort, productivity, and health.

With commercial HVAC systems accounting for nearly 45% of a building’s energy consumption, identifying and solving issues can save significant money, reduce downtime, and keep your environment comfortable.

Lee Company helps building managers and commercial property owners proactively troubleshoot their HVAC systems and address common problems. Here are some of the most frequent issues and how to handle them:

Common HVAC Problems in Commercial Settings

As employees and customers arrive at your commercial space each day, they trust that the air conditioner or heater will do its job without a hitch. Unfortunately, commercial HVAC systems can face various issues, particularly:

- If they aren’t properly maintained.

- As they age.

- During extreme seasonal temperatures.

Here are some common problems you might encounter:

Lack of Regular Maintenance

Just like a house, car, or other mechanical system, regular maintenance is crucial for your HVAC system’s longevity and efficiency. Without it, minor issues can snowball into major problems, leading to costly repairs or replacements. Are you scheduling regular maintenance checks for your commercial HVAC system? If not, it’s time to start.

System Short Cycling

System short cycling, where the HVAC system frequently turns on and off, can stress components and lead to higher energy bills. This issue often stems from an oversized unit, thermostat problems, or restricted airflow.

Is your system on and off more than usual? Regular inspections can pinpoint the cause and prevent the wear and tear that leads to expensive fixes.

High Energy Bills

With all the inflation happening in the world today, it’s no surprise that your energy bill is going up. But an unexplained or extreme increase could point to a problem with your HVAC system.

Inefficient systems, poor insulation, or outdated equipment can all drive up costs. If your energy bills seem unusually high and you don’t see an obvious cause, it’s time to schedule an inspection.

Malfunctioning Economizer

An economizer is an essential component of rooftop HVAC units in commercial buildings. It’s designed to cut cooling costs by drawing in outside air when it’s cooler than the indoor air.

Issues arise when its sensors fail or dampers stick, preventing it from operating efficiently. A study by the New Building Institute found that nearly two-thirds of examined rooftop units had faulty economizers.

Are you experiencing higher-than-expected cooling costs? It might be time to check your economizer.

Poor Air Quality

Did you know that productivity losses from employees either missing work due to illness or working while sick (presenteeism) cost U.S. employers about $2,945 per employee annually? Indoor air quality directly impacts the health and productivity of your employees.

Dust, mold, and pollutants can circulate through a poorly maintained system, leading to those costly absences. If your employees frequently get sick, it might be time to examine your HVAC system more closely.

Inconsistent Temperatures

Specific buildings and industry needs can make it challenging for your HVAC system to regulate temperatures. For example:

- A sprawling office building with multiple wings.

- An older multi-story commercial property.

- A facility packed with hot equipment and machinery.

- A tech hub brimming with computers.

If you constantly adjust the thermostat, deal with hot and cold spots, or have occupants complain about uncomfortable temperatures, there may be an issue with your HVAC system’s capacity or distribution.

Refrigerant Leaks

Refrigerant leaks reduce efficiency and can damage your HVAC system. A leak might be to blame if your HVAC isn’t cooling as it should.

The Environmental Protection Agency (EPA) rolled out new regulations under the Clean Air Act to phase out high global-warming potential (GWP) refrigerants like HFCs. These new rules aim to reduce environmental impact by encouraging low GWP or natural refrigerants.

Regular maintenance checks can catch leaks early, saving you from costly repairs and ensuring compliance with these new regulations.

Thermostat Malfunctions

Bumping up the thermostat a degree may seem minor, but it can add up to significant costs over time. A malfunctioning thermostat that misreads temperatures or fails to communicate with your HVAC system can lead to wasted energy and discomfort for occupants.

Older thermostats may not have the advanced features of newer models, such as programmability and remote access. Upgrading your thermostat can improve efficiency and make temperature control more convenient.

Airflow Problems

Are some rooms in your building stuffier than others? Blocked vents, dirty filters, and damaged ductwork can all contribute to restricted airflow in your HVAC system. This affects efficiency and leads to inconsistent temperatures throughout the building.

Regularly changing filters and inspecting ductwork for damage can improve airflow and prevent potential issues.

Dirty Filters

Of all the tasks on your to-do list, one of the easiest to overlook is changing the HVAC filters. But dirty filters can cause a domino effect of issues, from restricted airflow and reduced efficiency to increased energy bills and strain on system components.

Make sure your team knows how often to change the filters and that someone is responsible for regularly checking them.

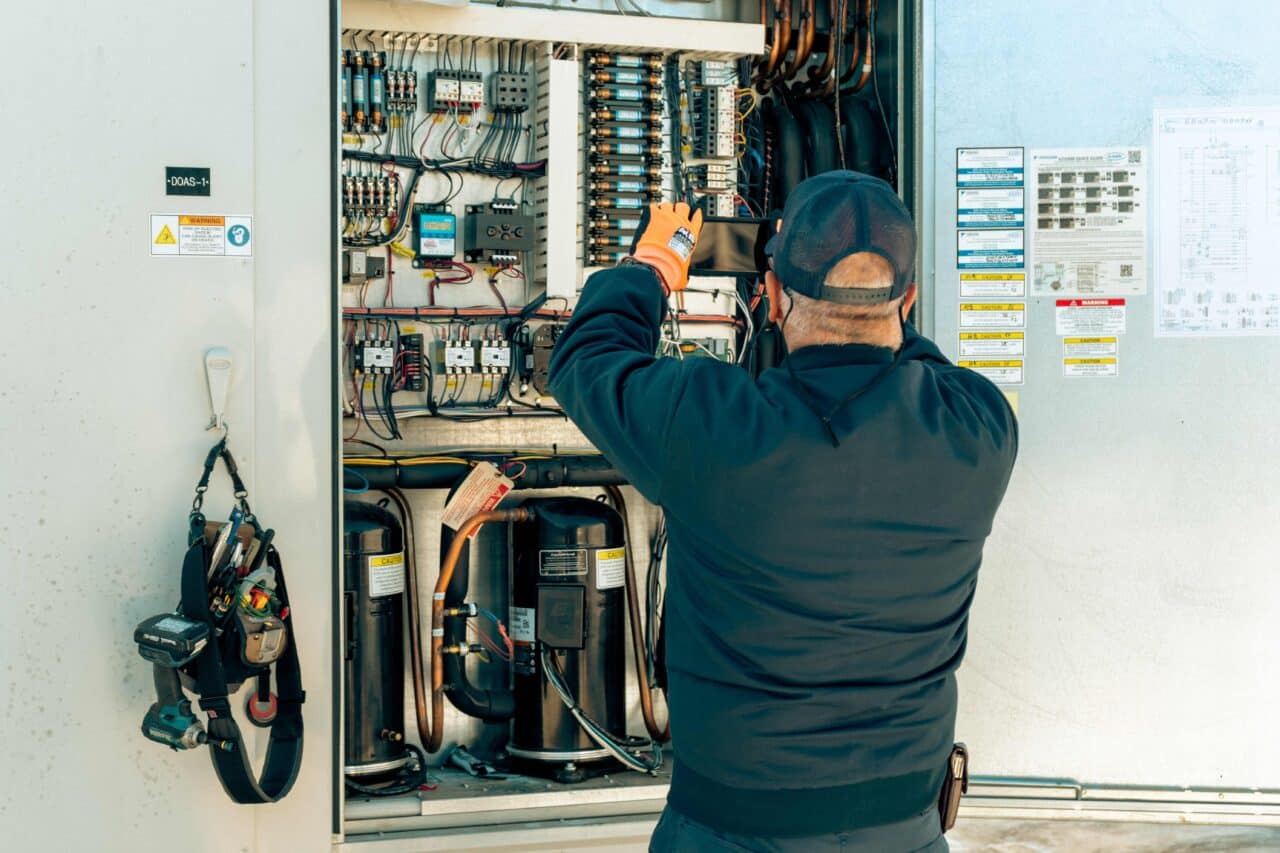

Electrical Issues

No one wants to deal with sudden power outages or electrical problems, but they can happen with HVAC systems. Electrical issues can cause a system to completely shut down or experience intermittent issues, impacting indoor temperatures and potentially causing a safety hazard.

Regular inspections by a professional help identify worn or damaged wiring and prevent major electrical failures that interrupt your business.

Water Leaks

Have you noticed any water or general dampness around your HVAC equipment? Condensate drain lines can clog and drip pans can overflow, leading to mold growth and, in extreme cases, even water damage to your property.

With the average water damage claim hovering around $24,000, you’ll want to catch and fix any leaks as soon as possible. Regular maintenance checks can prevent HVAC water leaks and keep your system running smoothly.

Unusual Noises

Your HVAC system should run relatively quietly, with a gentle hum or whoosh of air. The start-up and shutdown may make some noise, but rattling, banging, or squealing from your HVAC system are often early warning signs of underlying issues.

These noises could indicate loose parts, motor problems, or airflow issues. Regular maintenance and timely repairs help keep your system running smoothly and quietly.

Loose Evaporator Belt

In your commercial HVAC system, the evaporator belt plays a crucial role by driving the fan that circulates air. If this belt loosens, it can strain the pulley system, reduce fan speed, and eventually lead to a frozen coil, compromising your system’s efficiency and lifespan.

Watch for signs like unusual noises or reduced airflow, indicating a loose belt. Regular inspections can help avoid these disruptions and maintain optimal operation.

Frozen Coils

Frozen coils are a clear sign of a problem, often due to a loose belt, refrigerant leaks, blocked airflow, or dirty filters. This reduces efficiency and strains your system, leading to potential breakdowns and costly repairs.

If you notice frost or ice on your HVAC equipment, don’t wait to address it. Schedule a maintenance check to identify and fix the root cause before further damage occurs.

Identifying HVAC Problems

It’s easy to get caught up in the immediacy of day-to-day operations — your budget might be tied to other priorities, or you may have trouble finding time for maintenance. But being proactive about identifying potential HVAC issues is a strategic approach to cost management and is essential for effective capital planning.

Are you overlooking signs that could lead to bigger, more expensive problems? Do you inspect your commercial HVAC system regularly, or are you waiting for a breakdown to take action?

Performing regular visual inspections yourself or delegating this task to a trusted team member can help cut operational costs and prevent disruptive HVAC failures.

Symptoms and Signs to Watch For:

- Insufficient Heating or Cooling: Are all areas of your building maintaining comfortable temperatures?

- Inconsistent Temperatures: Do you notice varying temperatures from one room to another?

- Poor Indoor Air Quality: Are there complaints about stuffy or musty air?

- Unusual Noises: Are there odd noises coming from your HVAC equipment?

- High Energy Bills: Have your utility bills unexpectedly increased?

Tools and Techniques for Diagnosing:

- Visual Inspections: Regularly inspect your HVAC system for visible signs of wear and tear, like loose components, leaks, or anything out of place. This is the first line of defense in preventing significant issues.

- Thermostats and Sensors: Smart thermostats and sensors offer real-time data on your HVAC system’s performance, alerting you to inefficiencies or maintenance needs. These can help you keep a pulse on your equipment without adding extra tasks to your team’s schedule.

- Data Analysis: Collecting and analyzing data on your HVAC system’s performance can help identify patterns and potential problems, allowing you to take preventative action before a breakdown occurs. This can be as simple as tracking energy usage and comparing it to previous months or years, or implementing an automated building management system.

- Diagnostic Equipment: Advanced diagnostic tools like thermal imaging cameras, HVAC gauges, and refrigerant leak detectors require the expertise of a professional commercial HVAC technician. These tools can help professionals precisely pinpoint and resolve complex issues before they get worse.

Troubleshooting HVAC Issues

It’s the peak of summer in the Southeast, and your building’s HVAC system suddenly starts failing…

The air is stifling, employees are complaining, and productivity plummets. Customers visiting your property notice the sweaty environment, which might make them think twice about returning.

This scenario isn’t just inconvenient — it potentially damages your business reputation and operational efficiency.

How quickly can you identify and fix the problem before it impacts your bottom line?

Proactive Commercial HVAC troubleshooting can mitigate these risks and ensure smooth operations year-round. Here are some common issues and troubleshooting tips to keep in mind:

Insufficient Heating or Cooling

- Check Thermostat Settings: Ensure they’re set correctly for your desired temperature. Additionally, have thermostats calibrated annually by a professional to prevent inaccuracies that can affect system efficiency.

- Inspect Air Filters: A clogged filter can significantly restrict airflow, making equipment work harder and consume more energy. Facility managers should replace filters at least every three months or more frequently in high-dust environments.

- Examine Refrigerant Levels: If your system is low on refrigerant, it could indicate a leak. A certified technician who performs leak detection and repair services annually should handle this task.

Poor Airflow

- Inspect Ducts and Vents: Facility managers should ensure vents and returns are clear of obstructions. Consider hiring professionals to use inspection cameras for deep checks and to seal any leaks found.

- Check Blower Motors: HVAC professionals should conduct load testing to assess motor performance semi-annually to identify potential failures before they occur.

- Assess Air Filters: Replace dirty or clogged filters regularly. For environments with significant airborne debris, consult with a professional commercial HVAC technician to select the most suitable filters, such as HEPA, for the system.

Strange Noises

- Identify Sources of Noise: Facility managers can initially investigate noises but might need to use more sophisticated diagnostic tools, such as stethoscopes or acoustic imaging devices, which are best handled by professionals.

- Check for Loose Components: Secure any loose screws or bolts found during inspections. Checking and adjusting vibration dampeners should also be part of routine maintenance performed by HVAC professionals.

- Examine Motors and Fans: Facility managers can perform routine checks, but a qualified technician should be employed for detailed inspections and repairs, such as aligning belts and lubricating bearings.

High Energy Bills

- Assess System Efficiency: Facility managers should oversee energy audits conducted bi-annually by professionals to compare system performance and implement adjustments or upgrades.

- Check for Leaks: While facility staff can perform initial checks, professionals should perform pressurization tests to find and seal leaks in ductwork, especially in large commercial systems.

- Evaluate Insulation and Sealing: Facility staff can manage regular inspections, but upgrading insulation and ensuring it meets building codes should often involve professional contractors familiar with the latest standards and materials.

By clearly dividing tasks between:

- Regular upkeep that you can handle, and

- Specialized work that requires a professional HVAC technician,

…you can keep your commercial building’s HVAC system running efficiently, safely, and cost-effectively.

This approach ensures that routine maintenance is managed effectively while more complex issues are handled by experts. This helps extend the life of your system and avoid costly repairs.

Professional Commercial HVAC Services in the Southeast

From tackling insufficient heating or cooling to addressing strange noises, an HVAC system can be complex and intimidating to troubleshoot on your own.

Drawing on 8 decades of experience and a robust portfolio of successful projects – from routine maintenance at a Middle Tennessee police precinct to comprehensive system overhauls at major medical centers like Cookeville Regional and Parkridge – Lee Company stands out as a leader in commercial HVAC solutions in the Southeast.

Whether you need general maintenance, intricate repairs, or full-scale facility management, our FM2 team employs industry-leading technology and expertise to deliver results that meet your unique needs.

Don’t wait for a broken system to disrupt your operations — partner with Lee Company for reliable, efficient service that keeps your facility running smoothly day in and day out! Contact us today for commercial HVAC services in Tennessee, Kentucky, Alabama, and Georgia.

Ensure reliable commercial HVAC performance!

CALL US NOW AT 615.567.1000